Anagama kiln

In the Japanese wood-fired kiln of the anagama type the colours of the glaze are created by the firing process. The glazes are not applied; rather, the pieces are exposed to flames, smoke, glowing coal and ash. This makes for red and grey, and sometimes blue and purple colourings. The ash of the burning wood flies through the kiln and settles as fine dust over all the clay pieces; at temperatures above 1250°C, this dust combines with the clay and melts into a glaze. This naturally produced fly-ash glaze will vary in colour from a matt ochre haze to a transparent, deep green flow of glass – depending on where the vessel is positioned in the kiln.

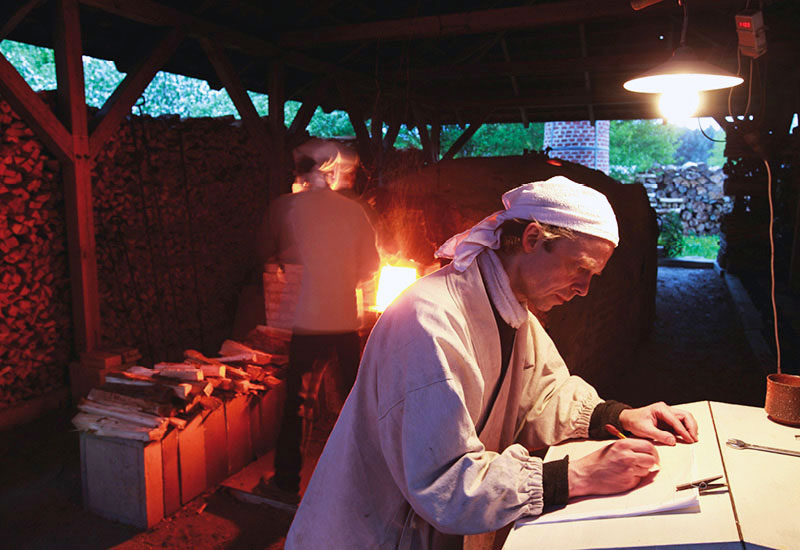

The kiln in Cismar is fired continuoulsy for four days. New wood is added every three minutes, all day and night. The colours are determined not only by the paticular mixture of clays, the stacking of the objects in the kiln, and the selection of types of wood, but also by the rhythm between oxidization and reduction, and the overall heat of the fire. Different types of clay work better in different locations within the kiln. The Westerwalder clay is mixed with crude or finely crushed sand, procellains or red clay in order to tune its character and physical properties to the varying conditions and different locations in the kiln. The preparation of the clay, with its particular combinations of pyrit and feldspat, mica and manganese, is done by hand in a traditional, Japanese manner. In this way, the clay maintains its natural consistency, and therefore produces especially lively surfaces.

Even the form of a particular vessel may be selected to make the best use of a location in the kiln. it makes a difference whether a vase is located close to actual burning fire, where parts of its surface may turn blue, or if it is located right under the ceiling, where there is a tendency toward clear, green glaze. At the front of the kiln red colours dominate, whereas in the back grey tones are more frequent. The character of the particular position becomes an integral part of the creative process. It draws out what is merely the potential of the form, and thereby completes the work of the potter.

In order to produce the colours and structures described above, the kiln must be fired in accordance with the prescriptions derived from the history and tradition of the Japanese ceramics. These prescriptions are based on the experiences that Japanese ceramicists have gathered over the the past four hundred years; they relate specifically on the ancient craft traditions associated with the tea ceremony.